CLU058 build with HLG-600H-54B drivers

- Thread starter mxrz

- Start date

mxrz

Member

I am planning to run the center COB softer to minimize the hotspot. I'll do some testing next week to figure out how much softer. Also, I'd never run the whole light assembly at more than 90% load, so this would be the absolute max, for the 12/12 cycle:1050 - 1320w in a 5x5 tent?

IMHO beyond overkill even w/ co2

Why not run 2x hlg-480h and use smaller chips?

That center hotspot is going to kill your PAR in the corners

1825 3500K90Min 9 COBS @2520 mA ON 5.375 PROFILE HEATSINK

24 SQ.FT. CANOPY 95% EFFICIENT DRIVER @9 CENTS PER KWH

Total power watts at the wall: 1282.11

Cobs power watts: 1218.01

Total voltage forward: 483.34

Total lumens: 156083.56

Total PAR watts assuming 10% loss: 419.33

Total PPF: 2241.08

PPFD based on canopy area: 1005.12

PAR watts per sq.ft.: 17.47

Cob efficiency: 38.25%

Power watts per sq.ft.: 50.75

Voltage forward per cob: 53.70

Lumens per watt: 128.15

Heatsink riser thickness / number of fins / fin's length: 0.38in/21/1.0in

Heatsink area per inch: 345.08 cm^2

Total heat watts: 755.17

umol/s/W: 1.84 LER: 335.00 QER: 4.81

Heatsink length passive cooling @120cm^2/heatwatt: 263 inches

Heatsink length active cooling @40cm^2/heatwatt: 88 inches

COB cost dollar per PAR watt: $0.86

Electric cost @12/12 in 30 days: $41.54

Electric cost @18/6 in 30 days: $62.31

Cost per cob: $40.0

Heatsink cost per inch cut: $2.52

Total cobs cost: $360.0

Total heatsink passive cooling cost: $662.76

Total heatsink active cooling cost: $221.76

For veg, I'll run it at 50% load.

nogod_

Well-Known Member

Gotcha, this was an exercise in 'wall watts dont mean shit'. I haven't enjoyed $.09/kwh for more than a decade so we live in different worlds. After seeing the numbers what made you choose this over a gavita?

In any event, I look forward to seeing it in action my friend.

In any event, I look forward to seeing it in action my friend.

I am planning to run the center COB softer to minimize the hotspot. I'll do some testing next week to figure out how much softer. Also, I'd never run the whole light assembly at more than 90% load, so this would be the absolute max, for the 12/12 cycle:

1825 3500K90Min 9 COBS @2520 mA ON 5.375 PROFILE HEATSINK

24 SQ.FT. CANOPY 95% EFFICIENT DRIVER @9 CENTS PER KWH

Total power watts at the wall: 1282.11

Cobs power watts: 1218.01

Total voltage forward: 483.34

Total lumens: 156083.56

Total PAR watts assuming 10% loss: 419.33

Total PPF: 2241.08

PPFD based on canopy area: 1005.12

PAR watts per sq.ft.: 17.47

Cob efficiency: 38.25%

Power watts per sq.ft.: 50.75

Voltage forward per cob: 53.70

Lumens per watt: 128.15

Heatsink riser thickness / number of fins / fin's length: 0.38in/21/1.0in

Heatsink area per inch: 345.08 cm^2

Total heat watts: 755.17

umol/s/W: 1.84 LER: 335.00 QER: 4.81

Heatsink length passive cooling @120cm^2/heatwatt: 263 inches

Heatsink length active cooling @40cm^2/heatwatt: 88 inches

COB cost dollar per PAR watt: $0.86

Electric cost @12/12 in 30 days: $41.54

Electric cost @18/6 in 30 days: $62.31

Cost per cob: $40.0

Heatsink cost per inch cut: $2.52

Total cobs cost: $360.0

Total heatsink passive cooling cost: $662.76

Total heatsink active cooling cost: $221.76

For veg, I'll run it at 50% load.

sixstring2112

Well-Known Member

Seems like a single de 630w cmh would be a better choice here idk.I am planning to run the center COB softer to minimize the hotspot. I'll do some testing next week to figure out how much softer. Also, I'd never run the whole light assembly at more than 90% load, so this would be the absolute max, for the 12/12 cycle:

1825 3500K90Min 9 COBS @2520 mA ON 5.375 PROFILE HEATSINK

24 SQ.FT. CANOPY 95% EFFICIENT DRIVER @9 CENTS PER KWH

Total power watts at the wall: 1282.11

Cobs power watts: 1218.01

Total voltage forward: 483.34

Total lumens: 156083.56

Total PAR watts assuming 10% loss: 419.33

Total PPF: 2241.08

PPFD based on canopy area: 1005.12

PAR watts per sq.ft.: 17.47

Cob efficiency: 38.25%

Power watts per sq.ft.: 50.75

Voltage forward per cob: 53.70

Lumens per watt: 128.15

Heatsink riser thickness / number of fins / fin's length: 0.38in/21/1.0in

Heatsink area per inch: 345.08 cm^2

Total heat watts: 755.17

umol/s/W: 1.84 LER: 335.00 QER: 4.81

Heatsink length passive cooling @120cm^2/heatwatt: 263 inches

Heatsink length active cooling @40cm^2/heatwatt: 88 inches

COB cost dollar per PAR watt: $0.86

Electric cost @12/12 in 30 days: $41.54

Electric cost @18/6 in 30 days: $62.31

Cost per cob: $40.0

Heatsink cost per inch cut: $2.52

Total cobs cost: $360.0

Total heatsink passive cooling cost: $662.76

Total heatsink active cooling cost: $221.76

For veg, I'll run it at 50% load.

CobKits

Well-Known Member

at 2.5A/130W the 1825s are only about 10% less efficient on PPFD/W than the popular [email protected] setup

so not sure why people are thinking this will have sub-gavita efficiency. those 1825s are meant to go the distance, 2.5A is less than half max wattage

so not sure why people are thinking this will have sub-gavita efficiency. those 1825s are meant to go the distance, 2.5A is less than half max wattage

Randomblame

Well-Known Member

Like your setup and thorough planning, well done!So according to RapidLED, the HLG-600H turns off when it's dimmed to 0V, but the HLG-150H (all lower models than the 320) will not, it will stay on, dimly lit... This kinda sucks, this means I can't control all three the same way. I would need a relay and a signal to shut it off, or upgrade it to the HLG-320H.

An additional problem is that all my fans are three pin 12VDC. The Coralux Storm can control fans, but only 4 pin PWM fans... gonna have to solve this one. I don't feel like buying another 9 PWM fans :/

You could take an ELG-150 it comes with the same dimming options like the bigger HLG-drivers and will shut off at 0V/k.

But 2% less efficiency driver-wise...

nogod_

Well-Known Member

Isn't 36.33% system efficiency sub-gavita efficiency?

Cob efficiency: 38.25%

so not sure why people are thinking this will have sub-gavita efficiency.

mxrz

Member

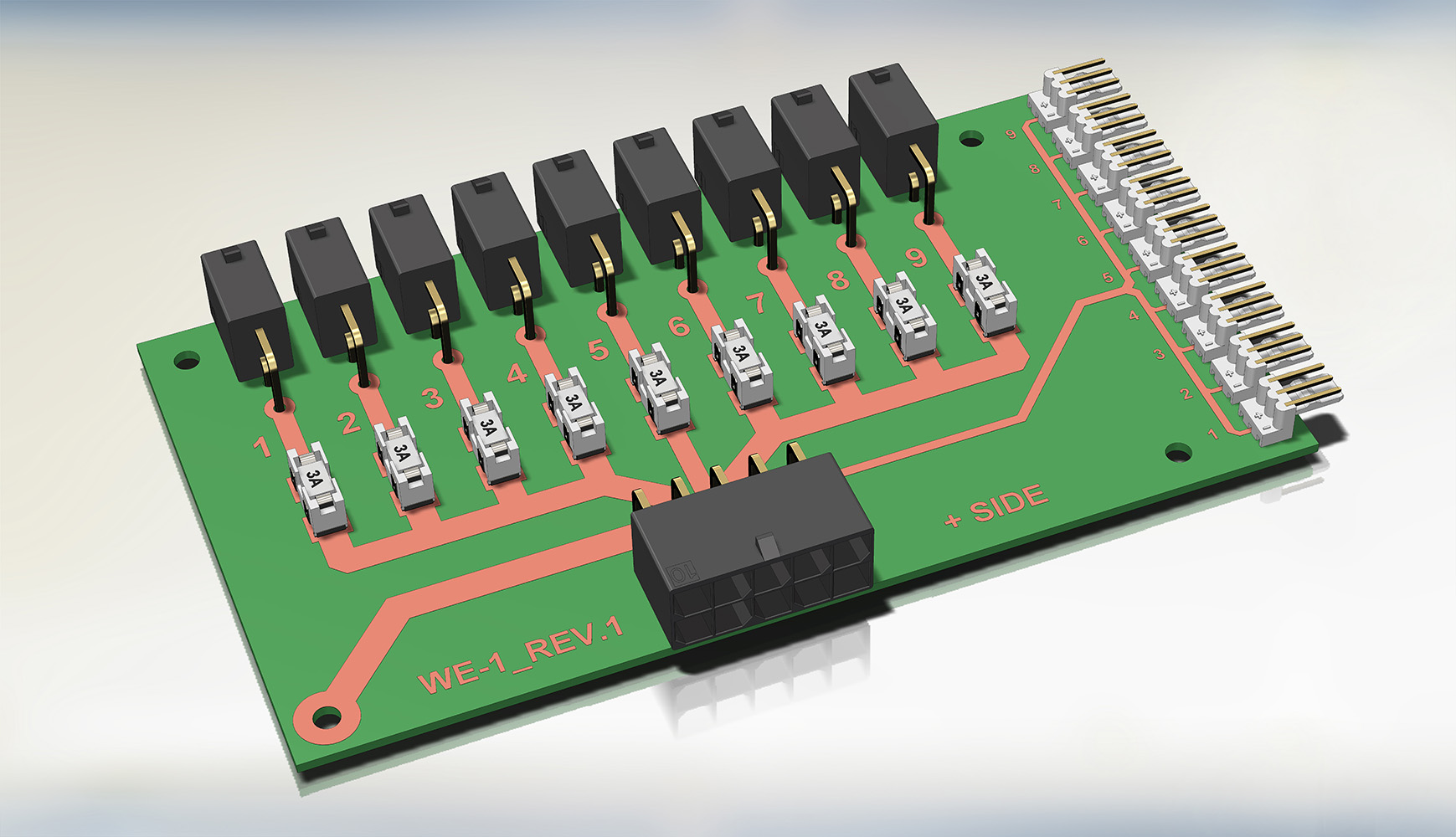

Updated my design with 80/20 T-Slot bars to make the assembly more modular:

Almost ready to test the COBs:

In terms of wiring, the COBs will be connected in parallel (4 per 600watt driver) with a 3A quick blow fuse protecting each COB. Since I plan to house the drivers away from the light, next to my tent, I'm going with 12awg wires to minimize voltage drop over the 10~12ft distance from the light assembly.

Almost ready to test the COBs:

In terms of wiring, the COBs will be connected in parallel (4 per 600watt driver) with a 3A quick blow fuse protecting each COB. Since I plan to house the drivers away from the light, next to my tent, I'm going with 12awg wires to minimize voltage drop over the 10~12ft distance from the light assembly.

CobKits

Well-Known Member

test them. i tried this once and they didnt blow anywhere close to where they were rated. you might want 2 or 2.5AIn terms of wiring, the COBs will be connected in parallel (4 per 600watt driver) with a 3A quick blow fuse protecting each COB.

1825s can take 5700 mA so maybe some sort of thermal protection might be more useful

with a 54B you have some voltage drop to play with, 12 seems like a good choiceI'm going with 12awg wires to minimize voltage drop over the 10~12ft distance from the light assembly.

CobKits

Well-Known Member

not really, noIsn't 36.33% system efficiency sub-gavita efficiency?

https://chilledgrowlights.com/independent-lab-reports/gravita-pro-1000-de-hps-at-1000w-goniometer-lab-report

citi also underspecs their cobs. if you went by datasheets they would also be sub-CXB3590 in efficacy when the clu058s are really a class or class and a half above them

nogod_

Well-Known Member

Isn't 36.33% < 36.41%?

not really, no

https://chilledgrowlights.com/independent-lab-reports/gravita-pro-1000-de-hps-at-1000w-goniometer-lab-report

citi also underspecs their cobs. if you went by datasheets they would also be sub-CXB3590 in efficacy when the clu058s are really a class or class and a half above them

xX_BHMC_Xx

Well-Known Member

IIRC Coralux makes a fan controller that will let you run 3 or 4 3-pin fans from one PWM signal...So according to RapidLED, the HLG-600H turns off when it's dimmed to 0V, but the HLG-150H (all lower models than the 320) will not, it will stay on, dimly lit... This kinda sucks, this means I can't control all three the same way. I would need a relay and a signal to shut it off, or upgrade it to the HLG-320H.

An additional problem is that all my fans are three pin 12VDC. The Coralux Storm can control fans, but only 4 pin PWM fans... gonna have to solve this one. I don't feel like buying another 9 PWM fans :/

mxrz

Member

Interesting, I'll look into it, thanks.IIRC Coralux makes a fan controller that will let you run 3 or 4 3-pin fans from one PWM signal...

xX_BHMC_Xx

Well-Known Member

Well done, looking very clean. Great build quality! Can't wait to see this thing done.Updated my design with 80/20 T-Slot bars to make the assembly more modular:

Almost ready to test the COBs:

In terms of wiring, the COBs will be connected in parallel (4 per 600watt driver) with a 3A quick blow fuse protecting each COB. Since I plan to house the drivers away from the light, next to my tent, I'm going with 12awg wires to minimize voltage drop over the 10~12ft distance from the light assembly.

I think most ELG drivers dim to zero.So according to RapidLED, the HLG-600H turns off when it's dimmed to 0V, but the HLG-150H (all lower models than the 320) will not, it will stay on, dimly lit... This kinda sucks, this means I can't control all three the same way. I would need a relay and a signal to shut it off, or upgrade it to the HLG-320H.

An additional problem is that all my fans are three pin 12VDC. The Coralux Storm can control fans, but only 4 pin PWM fans... gonna have to solve this one. I don't feel like buying another 9 PWM fans :/

Search for PC or computer fan speed controller, many options.

I use this for manual control, $1.89

http://www.ebay.com/itm/PWM-DC-Motor-Speed-Regulator-DC-Motor-Regulator-Switch-DC-6V-12V-24V-28V-3A/162193337868?_trksid=p2047675.c100005.m1851&_trkparms=aid=222007&algo=SIC.MBE&ao=2&asc=40130&meid=928db942591d406eaafaeddf866b6eb7&pid=100005&rk=5&rkt=6&sd=172651716586

Last edited:

mxrz

Member

I'd like to be able to control everything from the Coralux, so my fan controller needs to be able to use either the 10V analog channel or the 5V PWM channel as a trigger to turn my 12VDC fans on/off.I think most ELG drivers dim to zero.

Search for PC or computer fan speed controller, many options.

I use this for manual control, $1.89

http://www.ebay.com/itm/PWM-DC-Motor-Speed-Regulator-DC-Motor-Regulator-Switch-DC-6V-12V-24V-28V-3A/162193337868?_trksid=p2047675.c100005.m1851&_trkparms=aid=222007&algo=SIC.MBE&ao=2&asc=40130&meid=928db942591d406eaafaeddf866b6eb7&pid=100005&rk=5&rkt=6&sd=172651716586

mxrz

Member

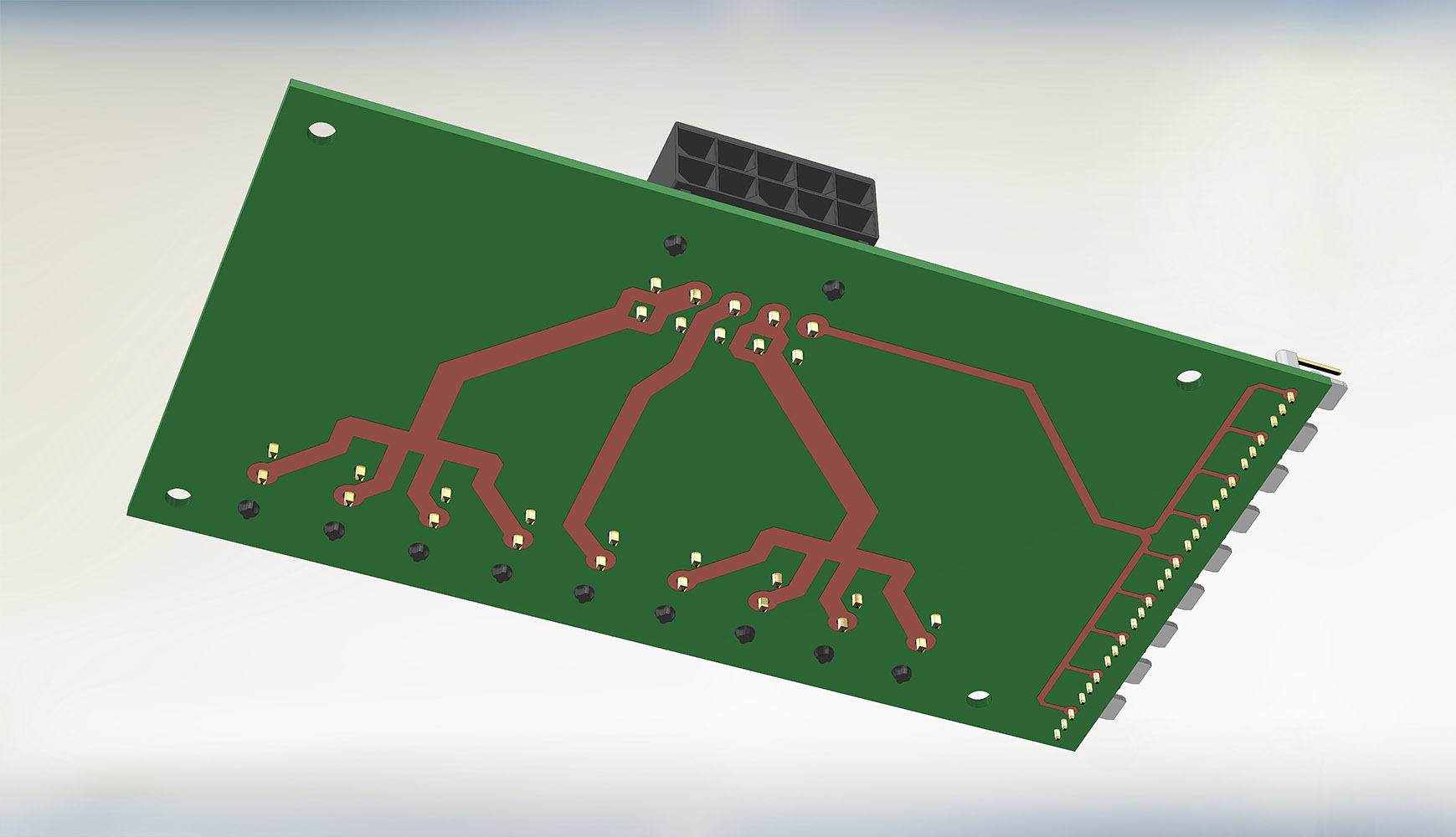

Power distribution board design, with surface mount 3A fuses and Molex Mega-Fit input/output connectors.

Next is going to be the power supply box that contain another PCB, all the Meanwell LED drivers, a 12V Meanwell DC power supply for the fans and the Coralux Storm LED controller.

The connection between the two PCBs is through the 10pin Mega-Fit Molex connectors, and the cable between them will be about 10ft long, made with 12AWG MIL spec wires (p/n M22759/34-22-9)

Next is going to be the power supply box that contain another PCB, all the Meanwell LED drivers, a 12V Meanwell DC power supply for the fans and the Coralux Storm LED controller.

The connection between the two PCBs is through the 10pin Mega-Fit Molex connectors, and the cable between them will be about 10ft long, made with 12AWG MIL spec wires (p/n M22759/34-22-9)

mxrz

Member

It was harder than I thought to source double sided 2oz thick copper clad board to make my PCB. 1oz is available everywhere, but not 2oz. Anyway, board is done.

Next step is building the harness with 12awg wires, Molex Mega-Fit plugs and snakeskin to wrap it up. Good thing I can borrow a Mega-Fit contact crimper at work to make the plugs... Molex wants around 400 USD for the tool.

Next step is building the harness with 12awg wires, Molex Mega-Fit plugs and snakeskin to wrap it up. Good thing I can borrow a Mega-Fit contact crimper at work to make the plugs... Molex wants around 400 USD for the tool.