Heisengrow

Well-Known Member

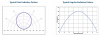

You mean like this?seems to be covered up.pretty goodyou could drive 5(20) cobs / (4)driver to get better spread over your squares

and squeeze out full load of the driver - because if Vf of your chip is ~37V

power on the wall is only ~155W (4 x 37V x 1,05A) ---> 31W / sqf

max. power would be ~209V x 1,05A ---> 43,9 / sqf

- cool down with cold beer and wire your fingers in parallel with your growing grow head room -

- cool down with cold beer and wire your fingers in parallel with your growing grow head room -