ChrisDuke

Well-Known Member

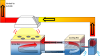

Ok do it yourself folk. This is what I'm throwing together tonite. Already built the water chiller out of an old humidifier last night. Tonite I plan on connecting the two reservoirs and building the ductwork. Might end up needing an inline fan to help push the air out, we'll see how that goes. Question is, what are the odds that thermosiphoning will be sufficient to keep water circulating without a pump? Guess there's one way to find out!