Damn nice work... Yes, the venturi design you settled on is great- the same design used in nutrient injectors. There is also another mod you can perform on your pump- called a mesh-mod where you use something like cut strips of scotch-brite pad for the impeller arms instead of the rigid plastic arms- and would have the venturi right before the pump like a powerhead (which is what the original mod was supposed to be on). It increases oxygenation alot and helps the bubbles become micro-sized to mix thoroughly with the liquid being pumped, although I think you're more than getting the job done as is with extreme simplicity... Great stuff man!

PS- can you tell me what you've found to make a good tea blend? Bat guano, worm castings, etc I assume, and how much material per gallons of water do you find is the best..? Reason I ask is because I might want to copy your brewer for my organic vegetable garden. I am going to get some red wrigglers and do vermicomposting as opposed to the traditional composting I've been doing. For now I only compost components left over from strictly organic fruits veggies and eggshells. But I've read that the worms are very effective as neutralizing toxins and can even make newspaper and carboard harmless and "organic", not to mention the additional benefits their enzymes impart to the soil...

I used 15mls of molasses per gallon as a carb and then a cup to two cups each of varying guanos depending on what stage growth you were in, but rarely did i add guanos as I already had my beds amended and this was used mostly as a beneficial bacterial tea. as much compost/castings as you wanna use but I just did a shovel scoop maybe less.

I like the powerhead idea, making the venturi right on the pump! I have my venturi intake facing inside the barrel because i tee and valve off the exhaust so i can connect a hose and use the pump to pump out to my plants rather than carrying 5 gal buckets. that is why the venturi inlet is faced inside the barrel, when im watering plants the venturi shoots tea back into the barrel and keeps the tea well mixed throughout the watering (this is super important!!), that and if i cut off the flow on the hose between pots, it allows the pump to still operate through the venturi (less strain on the pump)

the tea outlet is a foot above the surface of the water so i am combining the waterfall dissolved oxygen effect along with the venturi. this is an idea i stole when researching bio buckets and all the research about water falls providing the best DO. That and since ancient times, the best irrigation came from diverted streams and rivers and those streams and rivers are oxygenated by small waterfalls and breaking water tension over turbulence. I figured the beneficial bacteria present in streams and rivers that feed on decaying matter (or whatever) lived in water oxygenated in that manner so I would like to recreate that in my brewer.

now heres the trick with that tea brewer, once you have a colony of good bacteria built up in the system (which takes around 5 days) you can feed out almost all of the tea and just re up the ro or de chlorinated water add more carbs and keep brewing. the existing microbes will re populate the tea in 2 days max depending on your outside temps. so for most of my grow thats what I did, occassionally adding more compost and basically maintaining a perpetual tea. Besides, cleaning out barrels is un-fun. Also, you cannot keep your pump touching the bottom, no matter how solids handling capable the pump is, it will still work harder on the bottom. so i suspend the pump by about an inch.

I never got a microscope on that brewer, but the DO was more than enough as the smell never went to that tell tale ammonia, so the anaerobic bacteria couldnt live in it. it does get nice and foamy though, more than any 5 gallon brewer with an air pump ever made.

obviously this tea brewer is not good for fungal teas as they are fragile and the pump will own them. I do make sure the impeller is not sharp though. softer the better, although microbeman had done tests using a recirc brewer with a pump and his microscoped tests showed that forcing a tea out through sprayers was more harmful to the bacteria than having a pump recirculating. Infact the slides of pumped tea vs airpumped tea showed virtually no difference.

the main difference between my design and microbemans is the addition of the waterfall. Im not sure if he uses an impingement venturi or a flow through like mine, its been a while since i looked. but definitely 100% with suspended tea (meaning just dumping everything into the water) you must have a flow through venturi. suspended tea brewing eliminates the dead zones of hanging filter bag tea, and you dont have to buy filter bags (or clean them) the bio film build up on the bag clogs the mesh and requires that you insert an additional air line into the bag to keep it alive and flowing. so yeah, ditch the bags and its less cost/material/electricity for powering the extra air pump/ and I believe its way better for the compost to be circulating freely in the tea than trapped in a bag.

on that note, heres why I dont use worm castings:

1) its extra dirt in your brewer that will just settle to the bottom and mess things up. especially if youre buying your worm castings from the store, theyre the worst at cutting your castings with sand!

2) its easier to just use your own compost, i threw all my vermiculture worms into my compost anyways, so theres worm castings in it without having to filter them out over a screen and all that extra work. plus hey the worms are helping your compost break down, SWEET

I like optimizing and simplifying.

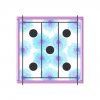

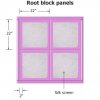

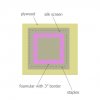

question: how many bio control nozzles would you put in the pods I designed?

ps- you know the "s" in abs plastic stands for styrene. the styrene scare just reminds me of the scare of pvc off gassing. and both have been debunked. I like plastics, its hard to avoid using plastic. im all about not killing my plants or myself or anyone else, I dont use pgr's and I am glad that people whistle blow. but if somethings safe and can help the community, im gonna use it.

ha, my barrel guy has some 50 gallon stainless steel barrels for $60 if anyone wants to make a super clean ss setup!