StAuggydogg

Active Member

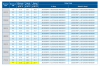

I am building my first light and really appreciate the help. I'm getting the strips from cutter and I'm going with 16--48v strips w/ 112 of the cree 2835's in 2700k at 90CRI... It will be a flowering specific light w/ no reds or blues or any other color diodes... I would like to be able to drive them to consume 6-650w.. and then wire in a pot to dim it as needed.

Cutter recommended the hlg600-48B but they're asking 80 bucks more than arrow, and that's before shipping, whereas the arrow price includes shipping. I was previously looking at greengenes strips w/ a pair of Osram 320w drivers that he has for 70 a piece.. I don't understand the whole programming of the drivers and haven't been able to get an answer via email from him. I thought they just functioned as a power supply/conditioner of sorts. Greengenes says the Osrams come programmed for 1440ma and 222v...

Can I use the Osrams programmed the way they come?

If I can't use the Osrams, what driver(S) would you recommend?

How would you recommend wiring the light?

What would be the max power consumed?

Sorry for the rambling and cobbled together sentence structure I've been up all night...lol

and thank you in advance for any help!

Cutter recommended the hlg600-48B but they're asking 80 bucks more than arrow, and that's before shipping, whereas the arrow price includes shipping. I was previously looking at greengenes strips w/ a pair of Osram 320w drivers that he has for 70 a piece.. I don't understand the whole programming of the drivers and haven't been able to get an answer via email from him. I thought they just functioned as a power supply/conditioner of sorts. Greengenes says the Osrams come programmed for 1440ma and 222v...

Can I use the Osrams programmed the way they come?

If I can't use the Osrams, what driver(S) would you recommend?

How would you recommend wiring the light?

What would be the max power consumed?

Sorry for the rambling and cobbled together sentence structure I've been up all night...lol

and thank you in advance for any help!