I'm making a box to hold 3-4 plants and planning on making it about 5.5ft tall, 4ft wide, and 1.5-2ft deep..

(about 40cu ft)

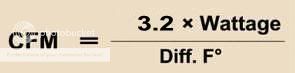

I'm planning on using a centrifugal fan (panasonic whisperline version, they make 120, 240, 480cfm)

I'm thinking 240cfm (maybe even 120cfm) would be enough for this application..any thoughts from someone who's done it?

I'm planning on having it pull air through a carbon filter -> cool tube -> out of the box.

Any thoughts on what would be best for tihs? If I make another box and have more ventillation than I need can I put a splitter and have it pull air from both boxes?

Any help/thoughts/ideas/anything is appreciated greatly. I'm trying to not waste money I don't have.

Thanks,

CreQ

(about 40cu ft)

I'm planning on using a centrifugal fan (panasonic whisperline version, they make 120, 240, 480cfm)

I'm thinking 240cfm (maybe even 120cfm) would be enough for this application..any thoughts from someone who's done it?

I'm planning on having it pull air through a carbon filter -> cool tube -> out of the box.

Any thoughts on what would be best for tihs? If I make another box and have more ventillation than I need can I put a splitter and have it pull air from both boxes?

Any help/thoughts/ideas/anything is appreciated greatly. I'm trying to not waste money I don't have.

Thanks,

CreQ