bassman999

Well-Known Member

Are the boards available separately?

Yep sure areAre the boards available separately?

@ChaosHunter

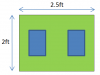

I will update the product listing with condensed info from this thread. Including my beautiful artwork and wire diagrams I made after

Regarding pre-drilled heatsinks for these boards

Processed at CINCINNATI HUB - USA

Estimated Delivery:Monday, December 12, 2016By End of Day

They will handle 75 watts passively.Hi are these heat sinks for passive or active cooling if running each panel at 75 W

at what ambient temperature?They will handle 75 watts passively.

75 watts at board with heatsink should be fine at upto 30C ambient.at what ambient temperature?

Any idea how much does the heat sink weighs?

75 watts at board with heatsink should be fine at upto 30C ambient.

Non anodized sample was 55C at 20-25C ambient. final version is anodized so it will run cooler.

Heatsink Weight:0.58kg

This test was done with no air movement.if a larger heat sink is used will it be more effective running the same config at higher ambients?

This test was done with no air movement.

Inside the tent the temps drops due to air flow.

How high is ambient temperature you plan to use this board in

This test was done with no air movement.

Inside the tent the temps drops due to air flow.

How high is ambient temperature you plan to use this board in

The heastink and boards can handle 60+C ambient worst case.i wanted something that can handle worst case scenario of upto 40C

This seems strange to me, air wont get trapped between them because its aluminum or soemthing?there is no thermal adhesive or paste needed for the heatsinks as the boards are alumininum backed.

Strips and boards have a much bigger surface area. Not like cobsThis seems strange to me, air wont get trapped between them because its aluminum or soemthing?

3590 can't be ran without a heatsink100w or less of power I can hold the boards in my hand while lit. Granted this is just during testing but nothing seemed to get overly hot just warm in hand. I'm a newb to the standard COB game so I'm not sure how hot a standard 3590 gets without a heatsink.