Rusty Shakelford

Well-Known Member

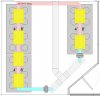

Hello Everyone,, I am in the process of up-scaling our Mother room, and I am at the point of figuring out the best way to connect the lighting for exhaust. We will be sealing the room and running (6) 400 watt MH. Of course I had planned on stringing them all together in the usual fashion, but did not think with this type of run, that it would be very efficient, so I am thinking a Trunk and Branch Setup instead.

I have attached a simple diagram in hopes of getting some Experienced feedback on how efficient this setup would be. Am I missing Anything? Should the Intake be Bigger? and I reducing OK? Any Ideas? Suggestions?

Let me know what you think

I have attached a simple diagram in hopes of getting some Experienced feedback on how efficient this setup would be. Am I missing Anything? Should the Intake be Bigger? and I reducing OK? Any Ideas? Suggestions?

Let me know what you think