KonopCh

Well-Known Member

Little help please, guys.

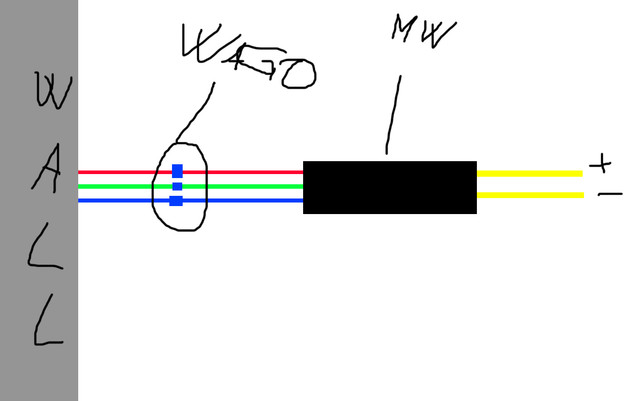

I want to replace these:

With two slots wagos.

I guess wiring is the same... example: blue to blue, red to red... in the same wago?

They're rated for 250V... I have 230V at the wall, so this is completly safe?

Another question, as I ordered only two slots wagos... Can I put two tiny wires from two computer fans together and wire them into one two-slot wago? So two fans on one 12V 1A adaptor with one wago.

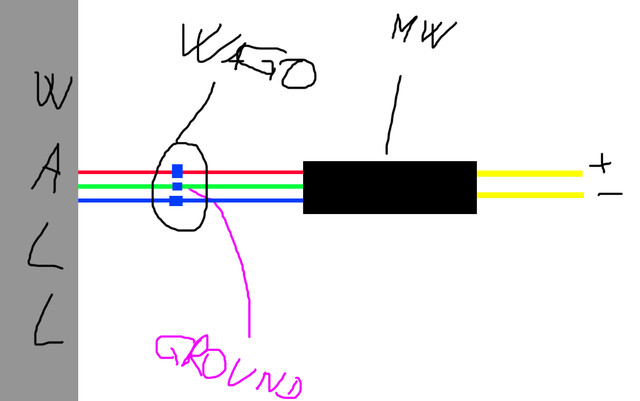

I want to replace these:

With two slots wagos.

I guess wiring is the same... example: blue to blue, red to red... in the same wago?

They're rated for 250V... I have 230V at the wall, so this is completly safe?

Another question, as I ordered only two slots wagos... Can I put two tiny wires from two computer fans together and wire them into one two-slot wago? So two fans on one 12V 1A adaptor with one wago.