NaturalFarmer

Well-Known Member

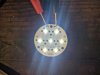

Using a $20 Presto electric griddle and a heat gun I tried this tonight for the first time using 7 emitter MCPCBs from this site.

http://led-mounting-bases.com/en/led-mcpcb/16806-mcpcb-diametre-40mm-pour-7-led-cree-xp-g3-compatible-optiques-khatod.html

I put the solder paste on all the pads and both contacts. I then warmed up the griddle slightly and put the emitters (4000k and 660 photo reds) on with the + going the correct way and then turned on the griddle to 400 degrees. I screwed up a few times and had to reheat again to remelt the solder and turn a few emitters but it got easier to lay it right as I went on. The first few times, I didn't warm the griddle first and was having a tough time placing the emitters correctly without bumping off target (room temp paste would have helped).

The solder paste will begin to look dry just before it melts. Once it does just push down slightly on the dome of the emitters and pop out any excess solder. The emitter will skate back over to the contact if you move it off. Wick the solder beads and there you have it.

Definitely a little nervous doing this the first time, but it really was easier then I thought it would be and was pretty fun. Now to start on the Osram Oslons.

Not the prettiest but not bad for a couple hours and a few bowls. I experimented with a few of the three emitter XP-Es to see how long I could keep it on with the emitters. Left it for twenty minutes (you can see the discoloration) and it still lit up.

Anyways hope some enjoys this, I would recommend giving it a shot.

https://www.amazon.com/Presto-07047-Touch-Electric-Griddle/dp/B0051XSIO6

Attachments

-

6.6 MB Views: 21

-

5.8 MB Views: 22

-

5.1 MB Views: 22

-

4.1 MB Views: 24