Score!

- Thread starter Go go n chill

- Start date

Go go n chill

Well-Known Member

I'm blessed with 2dads..... One is an outdoorsman the other is a hobbyists in electronics. I was able to score some items from his stash. He has passed from cancer, that's why I found my way to this site. God has ways. IMO

freemanjack

Well-Known Member

if that's a pair of heatsinks you could probably actively cool 2-300w of cob's but those fans look like older electronic equipt type fans, they may run on some fairly random voltages, if you have sets of 3 @ 12v dc you can power them in series off any 36-42vdc led power supply, yer still gonna need some bucks and engineering skills to assemble a working light but a pile of electronic bits is always a bonus when building, even if only to scavenge parts from.i got some goodies, maybe I can create something!

Go go n chill

Well-Known Member

Lol..... I'm not to bright sometimesI was making a pun about possible lighting solutions.

freemanjack

Well-Known Member

So sorry to hear that but yeah yer quite right, the plant chooses us, we don't choose the plant! Now start makin the medicine to save others from yer dads fate eh? Check out the Arthritis Cream thread in 'medicating' that recipe works equally as well for cancers as it does for arthritis and requires nothing more than yer waste schwag to cook it up.I'm blessed with 2dads..... One is an outdoorsman the other is a hobbyists in electronics. I was able to score some items from his stash. He has passed from cancer, that's why I found my way to this site. God has ways. IMO

Go go n chill

Well-Known Member

I have about 50 fans to choose from. The ones that I've visibly looked at are 12v dcif that's a pair of heatsinks you could probably actively cool 2-300w of cob's but those fans look like older electronic equipt type fans, they may run on some fairly random voltages, if you have sets of 3 @ 12v dc you can power them in series off any 36-42vdc led power supply, yer still gonna need some bucks and engineering skills to assemble a working light but a pile of electronic bits is always a bonus when building, even if only to scavenge parts from.

Go go n chill

Well-Known Member

Yes I need cobs and drivers. And I'd bet money he has drivers too. I've got the brains ..... Along with this site and its members to make it workif that's a pair of heatsinks you could probably actively cool 2-300w of cob's but those fans look like older electronic equipt type fans, they may run on some fairly random voltages, if you have sets of 3 @ 12v dc you can power them in series off any 36-42vdc led power supply, yer still gonna need some bucks and engineering skills to assemble a working light but a pile of electronic bits is always a bonus when building, even if only to scavenge parts from.

Go go n chill

Well-Known Member

I'm not in the Pacific Northwest, I'm in the Bible Belt But things are changing here for the better

freemanjack

Well-Known Member

Cool, well, attached to those pair of heatsinks were a whole bunch of power transistors, looked to be a kilowatt or so of em on each sink, they are very likely taken from a big pa amp or similar, most pa system amps use full wave bridge rectified power supplies and audio amps routinely run on 40v +/- dc which gives you either 80vdc or two 40vdc rails to drive leds off, power regulation may be an issue, as for leds constant current drivers are the norm, you are likely to have constant voltage transformer/regulators in your 'haul'. As long as your heatsink thermal regulation is sufficient (enuff fans) then thermal runaway is unlikely so constant voltage will regulate adequately.Yes I need cobs and drivers. And I'd bet money he has drivers too. I've got the brains ..... Along with this site and its members to make it work

freemanjack

Well-Known Member

if you look at the board of this fairly typical audio amp you can see the big torriodal transformer (donut shaped coil) if you trace the leads from that coil, 3 will go to the mains socket/switch/voltage selector and 3 will run into the bridge rectifier (the four little black cylinders just below the amp @ about 7 o'clock) if you power the amp and test for dc on the output of those diodes you should find the dc output of any amp/rectifier combination. Older transformers use big rectangular transformers and some bridge rectifiers are a single square unit with 4 terminals.

Go go n chill

Well-Known Member

He has so much stuff, I haven't been through all of it yet.

Go go n chill

Well-Known Member

I have 14 12v dc fans sizes from 2.75" to 3.25" widthif that's a pair of heatsinks you could probably actively cool 2-300w of cob's but those fans look like older electronic equipt type fans, they may run on some fairly random voltages, if you have sets of 3 @ 12v dc you can power them in series off any 36-42vdc led power supply, yer still gonna need some bucks and engineering skills to assemble a working light but a pile of electronic bits is always a bonus when building, even if only to scavenge parts from.

Go go n chill

Well-Known Member

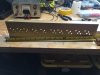

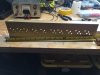

Who has enough experience with LED and heat sinks to tell me if these will work with all of the holes in them? My grow space is 42" wide x 32" deep . I was thinking about the cxm22's because they look like a good bang for the buck. Could I put 3 cobs on each ? And all the small black heat sinks enough to run the far red flower initiators ? Like I said earlier in this thread I have several 12 V DC fans and also 120 V fans and is there anything wrong with using 120 V fan

freemanjack

Well-Known Member

I would put a maximum of 100w's of cobs on those sinks actively cooled, the cobs will need to attach to undrilled areas, the holes will cause hotspots. You could use a piece of copper or ally sheet thermal pasted to the sink to bridge the holes. The 120v fans are likely to be high ft/min but noisy with it.Who has enough experience with LED and heat sinks to tell me if these will work with all of the holes in them? My grow space is 42" wide x 32" deep . I was thinking about the cxm22's because they look like a good bang for the buck. Could I put 3 cobs on each ? And all the small black heat sinks enough to run the far red flower initiators ? Like I said earlier in this thread I have several 12 V DC fans and also 120 V fans and is there anything wrong with using 120 V fan

View attachment 4016048 View attachment 4016050

Go go n chill

Well-Known Member

Ok thanks for giving me the info @freemanjackI would put a maximum of 100w's of cobs on those sinks actively cooled, the cobs will need to attach to undrilled areas, the holes will cause hotspots. You could use a piece of copper or ally sheet thermal pasted to the sink to bridge the holes. The 120v fans are likely to be high ft/min but noisy with it.

Go go n chill

Well-Known Member

@freemanjack, is there any way to fill the holes properly? Solder or epoxy compounds? You mentioned a sheet of copper or aluminum? How thick?I would put a maximum of 100w's of cobs on those sinks actively cooled, the cobs will need to attach to undrilled areas, the holes will cause hotspots. You could use a piece of copper or ally sheet thermal pasted to the sink to bridge the holes. The 120v fans are likely to be high ft/min but noisy with it.

freemanjack

Well-Known Member

Simple answer; thick enough to be perfectly flat to accept the flat cob heatsink without bending the cob. The longer answer is to consider heat like a fluid, we have an emission surface from which we need to conduct about half the total consumed wattage as heat, the holes in this case can be seen as 'blockages' to the passage of that heat. By attaching a piece of ally that is bigger than the cob, we can re-route that flow to the heatsink either side of the holes, so whatever bridging material you use will need to, as a bare minimum, replace the missing contact area made by the holes. One thought that occurred to me was if the holes are threaded, you could fill then with an appropriate size of studding/cut down bolt and file the cob side face flush with the heatsink. Steel will have a slightly lower thermal permissivity to ally or copper but far better than air alone, a little thermal paste on the threads will help too. If you go this route you might want to peen the bolt by hammering it from both sides before filing down flush to ensure it has a very tight fit in the threads and will not simply rattle about loose, just avoid any air boundaries regardless of how small, they are very effective insulators against conduction thru a solid.@freemanjack, is there any way to fill the holes properly? Solder or epoxy compounds? You mentioned a sheet of copper or aluminum? How thick?