@nvhak49 Yes it can be done. DIY COB is very customizeable so you can build for minimal up front cost/medium efficiency, balanced cost/efficiency, high efficiency/high cost, or very high efficiency/very high cost.

The higher the efficiency the more electrical savings but probably even more importantly, huge

heat reduction. The heat reduction can be due to COBs higher conversion efficiency than HPS, removing the infrared peak that occurs at 775nm with HID lamps, but mostly because you can get the same job done with so much less dissipation Wattage. This is thanks to the higher conversion efficiency, more efficient spectrum, reduced reflector losses and potentially a more even spread.

Here are some common designs for flowering

Vero29 with HLN-80H-42 (2.1A, 79W, 37.5% efficiency)

CXA3070 with

1.45A drivers (54W ea, 43.3% efficiency)

Those examples are very straight forward, one driver/COB

You can use drivers that run multiple COBs like the HLG-185H-C1400. They are dimmable, high quality, high efficiency and highly recommended to further reduce electricity and heat.

If you have questions about wiring check out the "how to power them sticky". There are threads dedicated to

heatsink info and

lenses/reflector info. Post up your build and questions. Good luck!

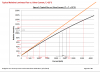

The designs that we currently recommend represent contributions from a bunch of different members. KNNA got us started with hand mount OSRAM golden dragons and we were building lamps that were 26% efficient. Now (7 years later) we can build lamps that are 65% efficient and cost less cost/PAR W.

The designs that we currently recommend represent contributions from a bunch of different members. KNNA got us started with hand mount OSRAM golden dragons and we were building lamps that were 26% efficient. Now (7 years later) we can build lamps that are 65% efficient and cost less cost/PAR W.