After seeing another users mods I bought one of these fans because I need exact control over air flow.

In this case I'm connecting a software pid controller to the fan to maintain temperature.

Hotter it gets, faster the fan goes.

Much to my surprise the wiring was nothing like depicted previously. It seems that Cloudline made a few changes. Initially hooking up the RPI to ground and the PWM cable half worked. Speed went up and down but it wouldn't go much past about 30%.

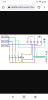

There is a diagram printed inside the cover. There are two bundles of wire. One for the AC power, one for the controller.

I used a molex connector to attach leads to the end of the control cable. Unfortunately in my screwing around I think I burned out the factory controller. No matter, it's of little use to me. There are 4 wires, I'm only using two of them, one is PWM GIPO18 and the other is ground. I'm using an EZ breakout board on the PI.

The PI is also going to be running lights, pumps, temp sensors as well as controlling the evap cooler during summer and a series of inline fans to control air flow.

High Power 5-36V 400W MOS Field Effect Transistor Trigger Switch Driver Module PWM Regulator Electronic Switch Control Board DC Motor Speed Controller.

There are many sources, they are cheap.

www.icstation.com

www.icstation.com

The control voltage is reversed on the Cloudline. In the case of Nodered this means sending a 0 if you want full and 100 for off.

At some point my plan is to add a diverter to the exhaust so part of the time the fan is recirculating grow room air through the carbon filter and part of the time it is exhausing hot air. I could do this with two inline fans but it's a bit cheaper to use one fan. I may be setting up some sub-zero unheated grows where the only heat source is the light so in situations like that, air control is crucial.

I was going to do this with an ESP32 but for whatever reason neither of the two I had would flash properly. I though about using an ESP8266 but I'm concerned about the slow clock speeds. I've heard mixed things and don't know what to believe. In theory you might be able to fit an ESP with power supply in the box.

In this case I'm connecting a software pid controller to the fan to maintain temperature.

Hotter it gets, faster the fan goes.

Much to my surprise the wiring was nothing like depicted previously. It seems that Cloudline made a few changes. Initially hooking up the RPI to ground and the PWM cable half worked. Speed went up and down but it wouldn't go much past about 30%.

There is a diagram printed inside the cover. There are two bundles of wire. One for the AC power, one for the controller.

I used a molex connector to attach leads to the end of the control cable. Unfortunately in my screwing around I think I burned out the factory controller. No matter, it's of little use to me. There are 4 wires, I'm only using two of them, one is PWM GIPO18 and the other is ground. I'm using an EZ breakout board on the PI.

The PI is also going to be running lights, pumps, temp sensors as well as controlling the evap cooler during summer and a series of inline fans to control air flow.

High Power 5-36V 400W MOS Field Effect Transistor Trigger Switch Driver Module PWM Regulator Electronic Switch Control Board DC Motor Speed Controller.

There are many sources, they are cheap.

High Power Dual MOS Tube Transistor MOSFET Trigger Switch Driver Module Adjustable PWM Regulator Switch Control DC 5V-36V 400W

Trigger Switch Driver Module. Dual MOS Trigger Switch Driver PWM Regulator. Mosfet Trigger Driver Module PWM Regulator Switch Control.

The control voltage is reversed on the Cloudline. In the case of Nodered this means sending a 0 if you want full and 100 for off.

At some point my plan is to add a diverter to the exhaust so part of the time the fan is recirculating grow room air through the carbon filter and part of the time it is exhausing hot air. I could do this with two inline fans but it's a bit cheaper to use one fan. I may be setting up some sub-zero unheated grows where the only heat source is the light so in situations like that, air control is crucial.

I was going to do this with an ESP32 but for whatever reason neither of the two I had would flash properly. I though about using an ESP8266 but I'm concerned about the slow clock speeds. I've heard mixed things and don't know what to believe. In theory you might be able to fit an ESP with power supply in the box.

Attachments

-

359 KB Views: 193

Last edited: