diggs99

Well-Known Member

Hey, getting ready to build these lights, want to have everything ready when the strips show up.

I plan to run 18 strips per 480w driver ( 3x4 fixture) i will be building 3 of them.

So 9 x 48" heatsinks per fixture, I was originally gonna solder my wiring, but now thinking i may just go with wagos with it being my first time.

Question one. which wagos do i need for this build? 5 ports? using 18g sold core wire. I think running everything in parallel.

I will be using the 1p68 waterproof connectors and junction boxes for ac/dc connects and remote dimmer if i go that route. May just go with the A drivers.

Are these power cords sufficient to buy/use? https://www.amazon.ca/gp/product/B003OQVGP0/ref=ox_sc_act_title_2?smid=A3DWYIK6Y9EEQB&psc=1

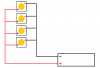

Last question, is there any good articles/diagrams/youtube videos that that could help show me how i will be wiring these strips in prallel?. I think i got the general idea, but would like to study and confirm i know wtf im doing before i start building.

I think the idea is all black (-) are tied together via a run(s) back to the - on driver

All red (+) tied together on a run(s) back to + on driver

Hopefully we can fill this thread with a bunch of good info so many newbs coming after me can utilize it.

I plan to run 18 strips per 480w driver ( 3x4 fixture) i will be building 3 of them.

So 9 x 48" heatsinks per fixture, I was originally gonna solder my wiring, but now thinking i may just go with wagos with it being my first time.

Question one. which wagos do i need for this build? 5 ports? using 18g sold core wire. I think running everything in parallel.

I will be using the 1p68 waterproof connectors and junction boxes for ac/dc connects and remote dimmer if i go that route. May just go with the A drivers.

Are these power cords sufficient to buy/use? https://www.amazon.ca/gp/product/B003OQVGP0/ref=ox_sc_act_title_2?smid=A3DWYIK6Y9EEQB&psc=1

Last question, is there any good articles/diagrams/youtube videos that that could help show me how i will be wiring these strips in prallel?. I think i got the general idea, but would like to study and confirm i know wtf im doing before i start building.

I think the idea is all black (-) are tied together via a run(s) back to the - on driver

All red (+) tied together on a run(s) back to + on driver

Hopefully we can fill this thread with a bunch of good info so many newbs coming after me can utilize it.