@MrDavis Only with an accurate spectroradiometer can you accurately measure PPFD in PAR W and umol/S to make a fair comparison between HPS and LED canopy intensity, although there are very significant differences in the spectrum and spread as well. Unfortunately, I do not have that $5000 tool on hand although I will consider acquiring one. So I start by looking at the lamp ppf (total photons emitted, 400-700nm). The way I see it

ppf is the lamps responsibility and ppfd is our responsibility (ppfd = photons in the canopy, umol/s/sq meter). In other words if you are determined to get the most out of the lamp's ppf, you can run an HPS bulb vertical and bare to somewhat reduce reflector losses, scatter losses and glass losses. Using LED, you can run them bare at low current, so close to the canopy that there are almost no losses to reflectors/lenses or scatter.

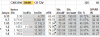

So in order to estimate the ppf of a white light lamp, we can convert from lumens if we know the LER. The LER can be estimated from an SPD curve which several awesome growers have done. The Cree CXA 3000K spectrum is 325 LER, according to Cree, which closely agrees with the SPD curve in the PDF. So the next part, we have to figure out how many lumens the lamp is emitting at each current. I estimate that from the Cree PDF data. They provide a Vf curve and a temp/current droop curve. Now we know our approximate lumens/W, which we can convert into

efficiency. We can also convert in umol/PAR W because Mr Flux provided the data when he calculated the LER. The CXA 3000K spectrum creates 4.88 umol/PAR W.

For 3000K LED, I recommend about

15 PAR W/ft² (15X10.76X4.88=788 ppfd) and would consider that very good intensity. With DIY LED you can get a much more even spread of light into the canopy (ppfd) than you can with HPS and that is very worthwhile effort. With lenses or reflectors you can get a more precise cutoff so less photons "miss" the canopy. You can scale it up as large as you need. You can increase intensity to 20 PAR W/ft² (20X10.76X4.88=1050 ppfd). Using COBs you can continue to increase intensity to the point that the plants turn white and die from light bleaching, but with perfect canopy temps LOL.

For HPS ppf, we can use the same method although there is some variance in our LER figures, 380-390. Large HPS lamps claim 130-150lm/W, which corresponds to 34-39% initial efficiency. So a 600W HPS put out about 225 PAR W. They experience about 20% reflector losses, 5-10% losses in the glass if there is a cover, maybe 5% to lateral scatter. So if the 600W HPS is covering a 3X3 canopy, you can expect about

18 PAR W/ft² (canopy average)

, which is very good intensity (initially.) You can get a decent spread of light, but the corners and edges will be a lot lower intensity than the center and the edges. See

growers house test of the 1000W HPS in magnum XXXl hood

In summary, we are looking at canopy intensity first and efficiency second. It is possible to strongly outperform the efficiency and intensity of HPS using COBs and many of us are doing it every day

(JUST JOKING

(JUST JOKING