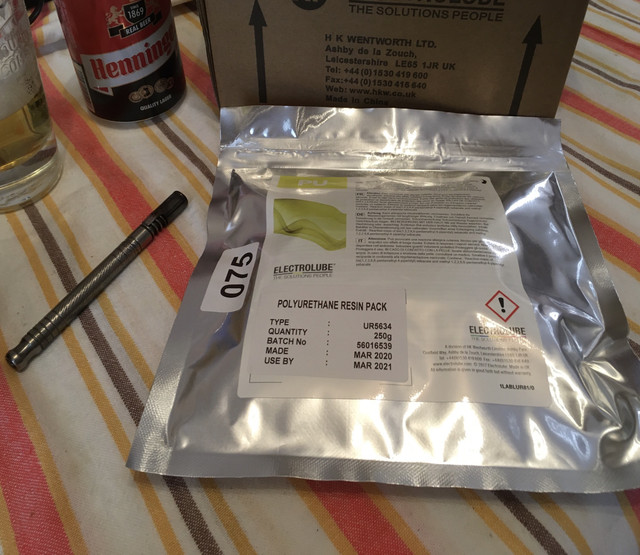

Just arrived !

Optically clear polyurethane LED potting compound formulated to protect LEDs from the environment. UV and mould resistant, suitable for indoor or outdoor.

electrolube.com

@Prawn Connery

I need your help ,please.

I will use this PU potting compound for covering the LED devices of 8x

Photo Boost strips from PLC.

Each strip has 96x LM301 having a height of approx 0.75 mm plus the added thickness of the solder and

4x XP-G3 which have a height of

~ 2.3mm ,plus the solder thickness.

All of them placed in a single straight line.

Since the mixed resin has a bit more viscosity than SAE 40 motor oil

(~1000 mPa s),

some kind of restraining is needed

around the straight line that the LEDs form ,so that the liquid resin will stay put and won’t overflow on the mcpcb ,while at the same time will encapsulate completely the LEDs.

After some brain-squeezing I’ve decided to use a 2 mm thick silicone Nano tape -cut in fine strips- and stick it on the mcpcb ,surrounding the line of LEDs.That will serve as a “mold”-sort of -and hopefully will keep the resin within it’s slim rectangular shape ,until it cures .

Afterwards ,the silicone nano tape strips will be removed ,since PU does not really adhere to silicone .

Of course ,before all that is done ,a thorough degreasing of the Photo Boost LED strips with IPA ,is rather obligatory.

Any advice ,suggestion and/or tips

are more than welcome .