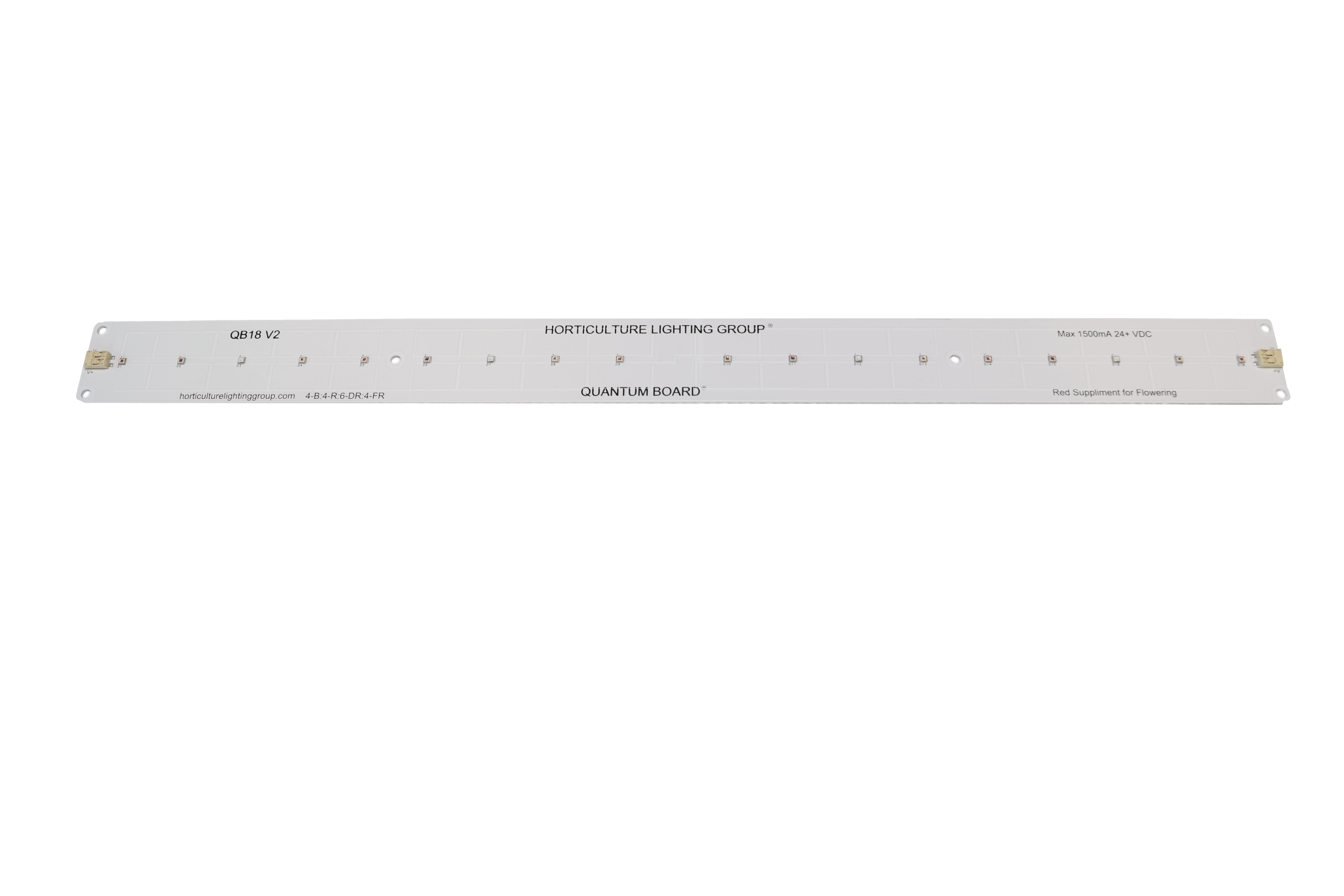

Less than 72 hours (Corona and all) and the strips are here, arrow turned out great.

Got the tray with 14 strips, now I really wonder how to utilize them best. Anyone has any idea on the min current I can run those w/o heatsinks, just an aluminum frame?

Was thinking about running 10 strips on hlg320 48 that I already have here, for 0.67a. the rated and tested current for those is 1.37, so running on half.

If heatsinks are a requirement still, would use a u or o channel aluminum frame as a heatsink.

Again, thanks for the heads up on those